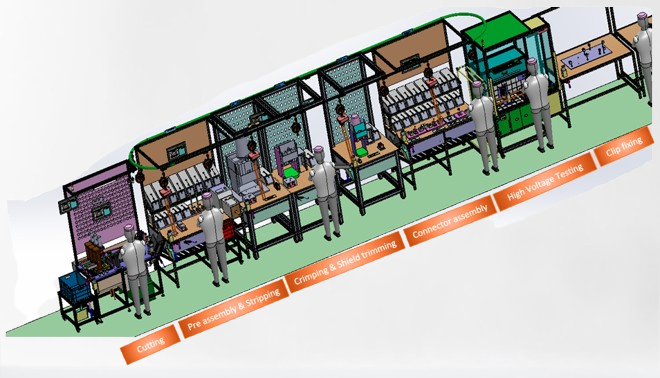

Charging Inlet Assembly Line

The entire harness will be processed, assembled and tested in single piece flow. The entire processing data like Strip length, Crimp dimensions, USW parameters, IR test, Continuity test, etc., will be recorded and the entire process will be in semi-automatic mode with 100% traceability. Any Rework / Rejections will be stored in the system with proper records. Maintenance and Quality checks are digitalized with ANDON displays to check the line out puts.